The UK heating industry is changing rapidly. For many qualified gas engineers, heat pumps are no longer a future concept. They are becoming part of everyday conversations with customers.

Most experienced engineers are highly confident in installing and commissioning boiler systems. The challenge is rarely the pipework or controls. The challenge lies in system design principles that differ from those used in combustion-based heating.

Heat pumps demand calculation-led thinking. They reward accuracy and expose assumptions. The good news is that the core principles you already understand, such as heat transfer, hydraulics and controls, remain directly relevant.

This guide outlines the system design fundamentals that separate a well-performing heat pump installation from one that results in reduced efficiency and callbacks.

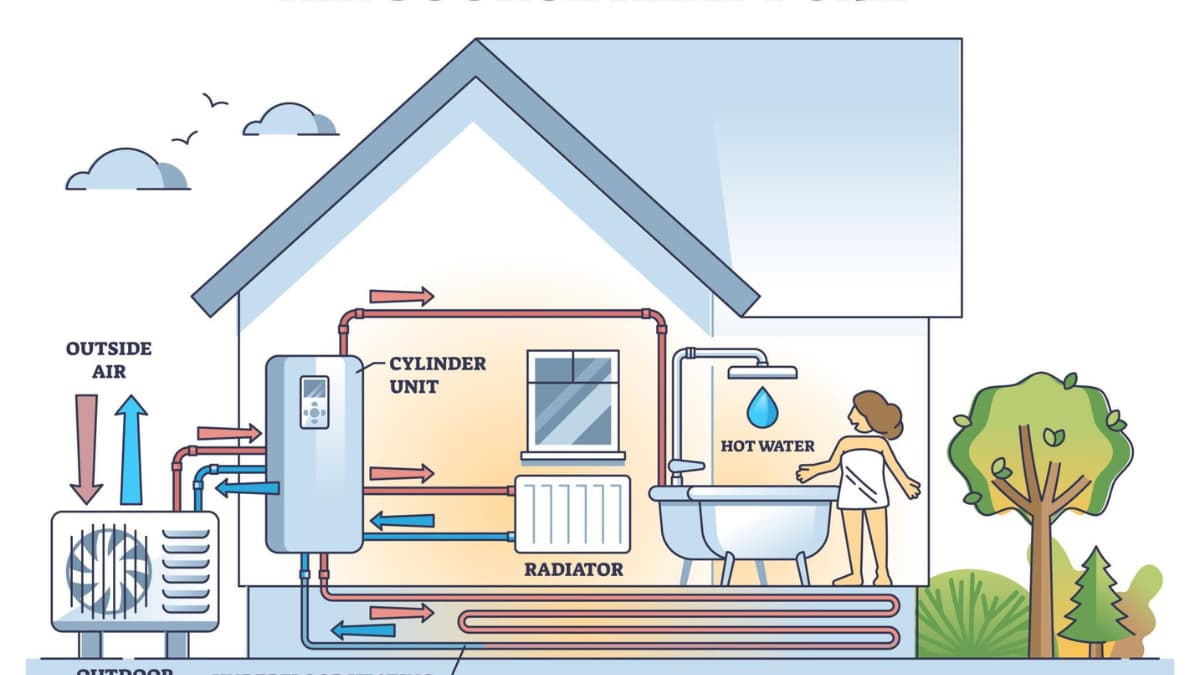

From High Temperature Boiler Systems to Low Temperature Heating Design

Traditional gas boiler systems commonly operate at flow temperatures between 70°C and 80°C. Even modern condensing boilers often run at 60 to 70°C in practice.

Heat pumps operate very differently. Most air source systems are designed to operate between 35°C and 55°C.

This lower operating temperature affects:

- Radiator output

- Flow rates

- Hydraulic performance

- System responsiveness

Boiler systems can often tolerate design inaccuracies because higher temperatures compensate for shortfalls. Heat pumps cannot.

Performance is achieved through design precision rather than temperature compensation.

Property Heat Loss and Accurate System Sizing

System design begins with calculating heat loss. It does not begin with selecting a unit.

Selecting a heat pump without calculating demand is equivalent to guessing the boiler’s output.

Fabric Heat Loss Example

Consider a three-bedroom semi-detached property:

Floor area: 95m²

Internal design temperature: 21°C

External design temperature: -2°C

Temperature difference: 23°C

After calculating wall, window, roof and floor losses, total fabric heat loss equals:

7,900 watts or 7.9kW

Fabric loss alone is not sufficient for final system sizing.

Ventilation Heat Loss Calculation Example

Ventilation losses are frequently underestimated.

Formula:

Ventilation Heat Loss in watts = 0.33 × Air Changes Per Hour × Room Volume × Temperature Difference

Example room:

Volume: 40m³

Air changes per hour: 1

Temperature difference: 23°C

0.33 × 1 × 40 × 23

= 303.6W

Across an entire property, ventilation may contribute 400 to 600 watts.

If fabric heat loss equals 7,900W

Add ventilation at 500W

Total heat loss becomes:

8,400W or 8.4kW

System selection must reflect the total calculated demand.

Heat Pump Selection and Oversizing Implications

With an 8.4kW heat loss:

Appropriate unit size would be 9kW.

Selecting a 12kW unit introduces oversizing.

Oversizing can result in:

- Reduced seasonal efficiency

- Short cycling

- Higher installation cost

- Increased compressor wear

Heat pumps achieve efficiency through stable modulation. Oversizing reduces operating stability.

Correct sizing protects both performance and reliability.

Emitter Performance at Reduced Flow Temperatures

Emitter performance changes significantly at lower flow temperatures.

Example radiator:

Manufacturer output: 2,000W at 75/65/20°C

The correction factor at 45/40/20°C is approximately 0.45.

Adjusted output:

2,000 × 0.45 = 900W

Room heat requirement:

1,850W

Available output at 45°C: 900W

Shortfall: 950W

Solutions may include:

- Increasing radiator size

- Installing double or triple panel radiators

- Adding a second emitter

- Installing low-temperature fan-assisted radiators

- Installing underfloor heating

Retaining undersized emitters is one of the most common causes of poor system performance.

Flow Rate, ΔT and Hydraulic Requirements

Gas boilers commonly operate at a temperature difference of 20°C. Heat pumps typically operate at a temperature difference of 5°C.

Flow rate formula:

Flow Rate in litres per second = Heat Output in kW ÷ (4.18 × ΔT)

Example:

8.4kW ÷ (4.18 × 5)

= 0.40 litres per second

Convert to litres per minute:

0.40 × 60 = 24 litres per minute

This flow rate is considerably higher than many boiler circuits are designed to handle.

Implications include:

- Increased pressure drop

- Pump selection becomes critical

- 15mm pipework may be insufficient

- Long pipe runs increase resistance

Hydraulic performance must be calculated, not assumed.

Technical Calculation Quick Reference

Use: A fast reference for core heat pump design calculations used in this article.

| Calculation | Formula | Worked example | Notes |

|---|---|---|---|

| Ventilation heat loss (W) | 0.33 × ACH × Volume (m³) × ΔT (°C) | 0.33 × 1 × 40 × 23 = 303.6W | ACH is air changes per hour. ΔT is the indoor minus outdoor design temperature. |

| Flow rate (L/s) | Heat output (kW) ÷ (4.18 × ΔT) | 8.4 ÷ (4.18 × 5) = 0.40 L/s | Heat pumps typically use ΔT ≈ 5°C. Boilers often use ΔT ≈ 20°C. |

| Flow rate conversion | L/min = (L/s) × 60 | 0.40 × 60 = 24 L/min | Useful for checking pipework capacity and pump selection discussions. |

| Radiator output correction (W) | Rated output × correction factor | 2,000W × 0.45 = 900W | Correction factor depends on system temperatures. Use manufacturer data where available. |

| DHW cylinder energy (kWh) | Volume (L) × 4.18 × ΔT (°C) ÷ 3600 | 200 × 4.18 × 40 ÷ 3600 = 9.29 kWh | Assumes 1L ≈ 1kg. ΔT is the desired temperature rise. |

| DHW recovery time (hours) | Energy required (kWh) ÷ Heat pump output (kW) | 9.29 ÷ 3 = 3.1 hours | Real-world recovery depends on coil performance and flow temperature. |

| COP | Heat output (kW) ÷ Electrical input (kW) | 9 ÷ 3 = 3.0 | Lower flow temperatures and correct emitters typically improve COP. |

Tip: For commissioning and compliance, always follow manufacturer instructions and relevant standards.

System Volume and Buffer Considerations

Many manufacturers specify a minimum system water volume.

Example requirement:

15 litres per kW

9kW heat pump × 15 litres

= 135 litres minimum system volume

If existing radiators and pipework provide 95 litres:

Shortfall equals 40 litres.

Solution options include:

- Installing a volumiser

- Installing a buffer tank

- Adjusting hydraulic configuration

System volume stabilises compressor operation and reduces cycling.

Domestic Hot Water Cylinder Performance

Heat pumps heat domestic hot water more gradually than combi boilers.

Example:

Cylinder volume: 200 litres

Temperature rise: 10°C to 50°C equals 40°C

Energy required calculation:

200 × 4.18 × 40 ÷ 3600

= 9.29kWh

If the heat pump output in hot water mode is 3kW:

9.29 ÷ 3

= 3.1 hours recovery time

Design considerations include:

- Larger coil surface area

- Lower primary flow temperature

- Legionella cycle programming

- Cylinder insulation quality

Recovery expectations must be discussed at the design stage.

Seasonal Performance and System Efficiency Metrics

Heat pumps are evaluated using the Coefficient of Performance.

Example:

Heat output: 9kW

Electrical input: 3kW

COP = 9 ÷ 3 = 3.0

If poor design increases electrical input to 4kW:

COP becomes:

9 ÷ 4 = 2.25

Over a heating season:

COP of 3.0 may require 6,000 kWh of electricity

COP of 2.25 may require 8,000 kWh of electricity

Design quality directly affects running costs.

Emitter sizing and flow temperature control are major influencing factors.

Retrofit Property Assessment and Suitability

Not all properties are immediately suited to standalone heat pumps.

Example:

Calculated heat loss: 14kW

Maximum available single-phase heat pump: 12kW

Possible responses include:

- Improving insulation

- Installing a hybrid system

- Upgrading electrical supply

Assessment factors include:

- EPC rating

- Glazing specification

- Loft and wall insulation

- Existing emitter capacity

- Electrical consumer unit capacity

System suitability should be established before equipment specification.

Hybrid System Design Principles

Hybrid systems combine heat pump and boiler technology.

Example:

Heat pump output at -2°C: 7.5kW

Property heat loss at -2°C: 8.5kW

Shortfall: 1kW

Boiler supplements load below the defined outdoor temperature.

Hybrid systems can:

- Reduce peak electrical demand

- Provide transitional confidence

- Maintain performance during extreme conditions

This approach allows for the gradual adoption of renewable technologies.

Frequent Design Errors During Transition

Common issues include:

- Oversizing heat pumps

- Retaining undersized radiators

- Ignoring flow rate limitations

- Underestimating system volume

- Incorrect outdoor unit positioning

- Miscalculating domestic hot water recovery

Most design failures originate from applying boiler-based assumptions to low-temperature systems.

Structured training significantly reduces these risks.

Commercial Impact of Correct System Design

Accurate system design leads to:

- Reduced call-backs

- Higher customer satisfaction

- Improved seasonal performance

- Stronger professional reputation

- Confident system specification

Design competence supports long-term business growth.

Heat Pump Training With Staffordshire Training Services

Transitioning into renewables requires a structured understanding of:

- Heat loss calculations

- Emitter recalculation

- Hydraulic and flow design

- System volume requirements

- Domestic hot water integration

- Commissioning and optimisation

At Staffordshire Training Services, engineers train in a purpose-built environment that bridges the gap between traditional gas systems and low-carbon heating technologies.

Our heat pump courses provide practical, calculation-led training that builds confidence in system design, installation and commissioning. Alongside this, our wider renewable energy training programmes support engineers expanding into modern low-carbon heating solutions.

Courses focus on practical calculations, real-world system layouts, hydraulic understanding and regulatory awareness.

Engineers leave with the confidence to design and install heat pump systems correctly from the outset, while developing the broader renewable skillset increasingly demanded across the UK heating sector.

Renewable competence expands existing skills. It strengthens technical capability and future-proofs your business in an evolving heating market.

Related Articles

- Quick Heat Pump Guide for Installers

- Advantages of Training in Both Heat Pump Technologies

- Choosing Between Combined or Focused Heat Pump Training

- Adding Renewables to Your Heating Business

- Careers in Renewable Energy for Gas and Heating Engineers

Prefer an AI Summary?