As the UK transitions towards cleaner, low-carbon heating, heat pumps are becoming a central feature in both new build and retrofit heating projects. For engineers already working in plumbing, heating or renewables, now is the ideal time to build your understanding of heat pump systems and start offering them as part of your services.

At Staffordshire Training Services, we help skilled professionals develop the knowledge and confidence they need to work safely and competently with these modern systems. This guide provides a practical overview of the essentials every installer should know before working with heat pumps.

Heat Pumps

Heat pumps are low-carbon heating systems that transfer ambient heat from a source (air or ground) into a building to provide heating and hot water. Rather than burning fuel directly, they operate using electricity and a refrigerant process, offering greater efficiency compared to traditional systems, such as gas boilers.

They are often used in well-insulated homes or commercial settings and are considered a key part of the UK’s plan to reduce emissions and meet its net-zero targets. Once installed correctly, heat pumps provide a reliable and energy-efficient source of heat, with lower running costs over time.

There are two main types commonly used in the UK: air source and ground source.

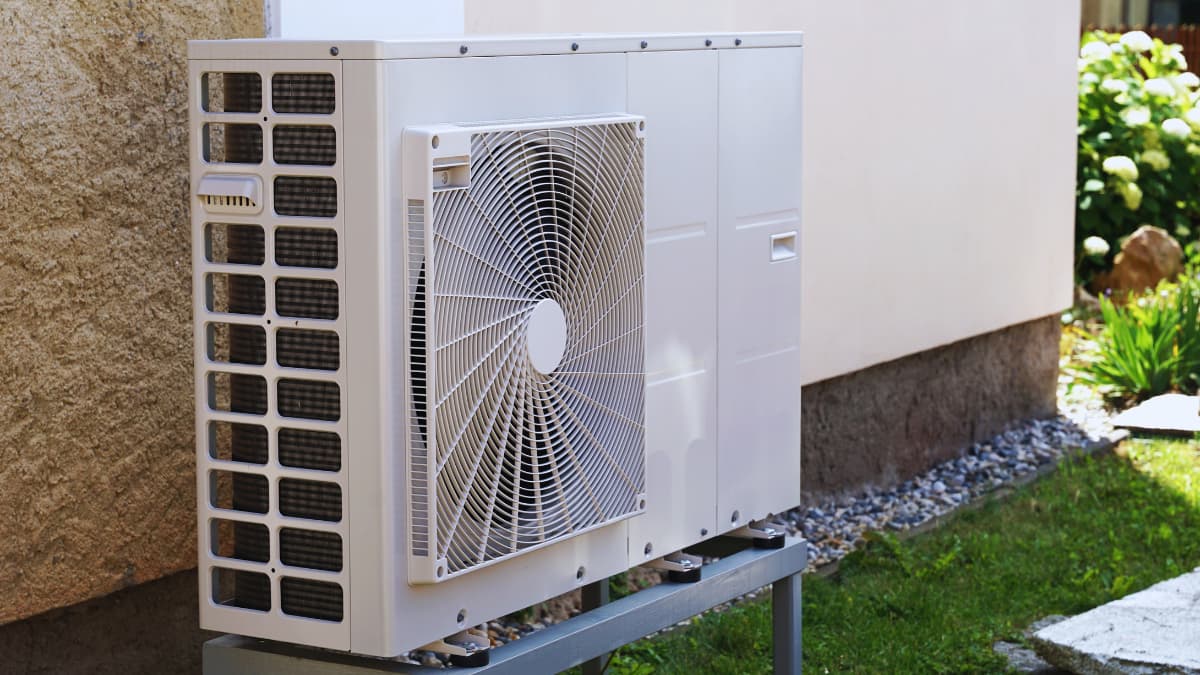

Air Source Heat Pumps

Air source heat pumps absorb heat from the outside air and transfer it indoors using a heat exchanger. These systems can work efficiently even at low external temperatures, making them suitable for most regions of the UK.

Features of air source systems include:

- Easier and quicker to install than ground source

- Ideal for retrofit projects and smaller domestic properties

- Works well with low temperature radiators or underfloor heating

- Typically installed externally with minimal disruption

They are particularly popular due to their relatively low installation costs and compact design. Installers must be confident in siting the outdoor unit, connecting to hydraulic emitter circuits, and commissioning the system effectively. Routine servicing also forms part of the installer’s responsibility and helps ensure long-term performance.

Ground Source Heat Pumps

Ground source heat pumps extract stored heat from the ground using a buried loop of pipework called a collector circuit. This heat is drawn into the system and transferred to the property’s heating and hot water circuits through a heat exchanger.

Ground source systems offer:

- Greater efficiency in the long term due to stable ground temperatures

- Suitability for new builds or properties with sufficient land area

- Compatibility with larger homes or buildings with consistent heating demand

Installation is more complex and typically involves trench digging or borehole drilling, depending on site conditions. Installers must be familiar with collector loop design, sizing calculations, and the safe commissioning of non-refrigerant components.

Installation Essentials

Installing a heat pump system successfully depends on sound design and careful preparation. It is not a case of removing a boiler and fitting a new unit. The performance of the system relies on matching the correct output with the building’s heat demand, which means:

- Conducting accurate heat loss calculations

- Designing the system for low flow temperatures (typically 35–55°C)

- Ensuring the property has appropriate insulation

- Selecting suitable emitters, such as underfloor heating or oversized radiators

Hydraulic integration with the existing system should be carefully planned, especially in retrofit scenarios. Engineers must be confident in connecting buffer vessels, domestic hot water cylinders, and controls. While most installers will be working with non-refrigerant circuit systems (as taught in Level 3 LCL Awards courses), safe handling, pressure testing and system flushing are still critical skills.

Installation Challenges

Even well-trained engineers may encounter challenges on heat pump jobs. Some of the most common include:

- Undersized emitters – These reduce efficiency and make it harder to maintain comfort

- Incorrect flow rates or system balancing – This can lead to noise, inefficiency or system faults

- Inadequate system design – Results in poor performance or customer dissatisfaction

- Overpromising performance – It is essential to manage customer expectations and explain how heat pumps operate differently from boilers

Clear communication, proper commissioning and quality aftercare all contribute to better outcomes and happier clients.

Training Routes For Installers

At Staffordshire Training Services, we offer accredited renewable energy training courses specifically designed for qualified heating and plumbing engineers seeking to transition into renewables.

Renewable training programmes include:

- Air Source Heat Pump Systems (Level 3) – A focused 3-day course covering installation, commissioning and servicing

- Ground Source Heat Pump Systems (Level 3) – A 1-day focused course for engineers with suitable background knowledge

- Combined Heat Pump Systems (Level 3) – A 4-day course covering both air and ground source technologies

- Low Temperature Heating and Hot Water Systems (Level 3) – Recommended to support the design of efficient systems

- Energy Efficiency for Domestic Heating and Hot Water – Covers regulatory compliance and best practice

These courses are accredited by LCL Awards and delivered by qualified instructors with real industry experience. They focus on non-refrigerant circuit systems, making them ideal for heating engineers who want to expand their skills without needing full F-Gas certification.

Next Steps For Installers

Once trained, many engineers go on to register with a Competent Person Scheme (CPS) or the Microgeneration Certification Scheme (MCS), which helps them win more work and meet compliance standards. Being certified also builds trust with customers who are investing in a future-proof heating solution.

Whether you are working independently or part of a growing business, gaining the skills to install and maintain heat pumps gives you a real edge in a competitive market. At Staffordshire Training Services, our goal is to ensure you leave confident, capable and ready to succeed in the renewables sector.

Related Articles

- Adding Renewables to Your Heating Business

- Careers in Renewable Energy for Gas and Heating Engineers

- The Future of Heating with Renewables

- Advantages of Training in Both Heat Pump Technologies

- Choosing Between Combined or Focused Heat Pump Training

Prefer an AI Summary?